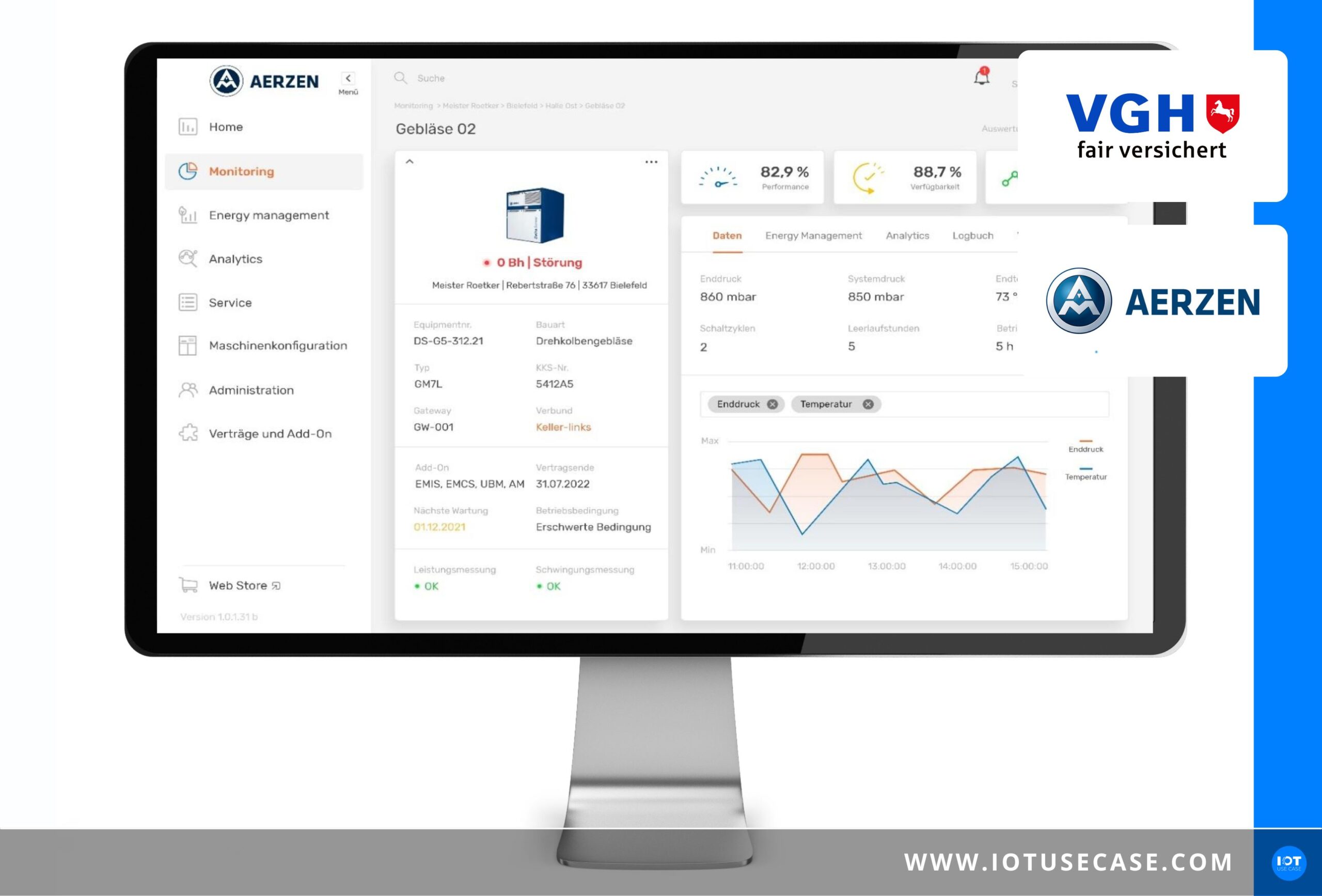

This podcast episode shows how Aerzen Digital Systems is able to offer data-driven services for machinery and equipment not only to mechanical engineering companies, but also to key partners such as insurance companies. Among other things, digital services create the potential to understand customer applications even better and generate additional revenue. VGH Versicherungen uses the data that Aerzen Digital Systems collects and processes for fast claims settlement and for new approaches in the insurance business. At second glance, surprisingly many similarities between the seemingly so different participants are revealed here. The case of insurance is presented in this episode as one perspective of data-driven business models.

Episode 86 at a glance (and click):

- [14:38] Challenges, potentials and status quo – This is what the use case looks like in practice

- [23:57] Results, Business Models and Best Practices – How Success is Measured

- [31:47] Solutions, offerings and services – A look at the technologies used

Podcast episode summary

Every ten minutes, an insured machine damage occurs in Germany. Whether unforeseen operational damage due to operating or material errors, short circuits and overvoltage, or damage due to frost and ice: the fact is, in the event of a failure there is a risk of high losses, which in the worst case can also mean the end of the company. Anyone who depends on the proper functioning of their machinery and equipment in their daily business operations should therefore always protect themselves with insurance. In this way, damage can be covered by repair, the replacement purchase or, in the case of a total loss, the current value.

Furthermore, live data from machines and systems is increasingly being used to detect dangerous situations in advance, to monitor them seamlessly and thus, for example, to initiate necessary maintenance work in good time – before damage occurs! Sharing this data with the insurer now also brings some advantages. What is the concept in the industry here? Is there such a thing as discounts, bonus miles, or better premiums by reducing risk? We clarify these questions and more in today’s episode of the IoT Use Case Podcast with Madeleine Mickeleit.

Aerzen Digital Systems is the digital unit of the AERZEN Group and subsidiary of Aerzener Maschinenfabrik GmbH. Florian Breker (Business Consultant IoT & Data Science, AERZEN Digital Systems) will be the company’s guest speaker. He brought along Carl Brand, claims adjuster at VGH Insurance. Among other things, the two explain what new technology trends are emerging and what added value data-driven services and services bring to a wide range of stakeholders.

Podcast interview

Every ten minutes in Germany, an insured machine damage occurs. Whether unforeseen operational damage due to operating or material errors, short circuits or damage due to frost and ice. The fact is: In the event of a default, there is a risk of really high losses, which in the worst case can also mean the end of a company.

Anyone who depends on the proper functioning of their machinery and equipment in their daily business operations should therefore naturally be covered by insurance. But they should also think about the use of data and what potential it offers.

Today, Carl Brand, claims adjuster at VGH Versicherungen, and Florian Breker from Aerzen Digital Systems will be there to provide impetus. They present the insurance-relevant use cases of Aerzener Maschinenfabrik – the world’s leading manufacturer of twin-shaft rotary lobe machines – and answer the questions of which data and business models will be relevant here today, but also in the future.

Florian, the first question directly to you: Where are you at right now?

Florian

Today I am in the beautiful Pied Piper town of Hamelin. We are based here with our digital team a few kilometers away from our machine factory in the Hefehof. This is a former yeast factory built in the Gründerzeit style, where we sit with about twenty colleagues, together with the technology and start-up center of the city of Hameln and some other companies. We are working on the digital solutions for our machines here.

Aerzen is also a place, isn’t it?

Florian

Exactly! Aerzener Maschinenfabrik takes its name from the town of Aerzen, so to speak. That’s about ten or twenty kilometers from Hamelin. However, for the purpose of infrastructural connection and Co. we have based ourselves here directly in the city of Hameln.

Cool – and Carl, I don’t think you’re that far off, are you? You are based in Hanover.

Carl

That’s right, I’m based in Hanover, but I’m sitting in my home office today. I am in the district of Herrenhausen, perhaps known to some for the royal baroque gardens and the castle with the beautiful fireworks always in the summer.

If you have never been to Hannover: The Herrenhäuser Gardens are a must!

Let’s start into the topic. Florian. Your colleague Ricardo from Aerzen Digital Systems has been here before. I’m totally excited about today’s topic. For those who do not know you yet: You are with Aerzen Digital Systems the digitalization specialist in the Aerzen Group. Founded as a wholly owned subsidiary of Aerzener Maschinenfabrik GmbH. You draw on 150 years of experience in mechanical engineering.

But now you are also active in the business field of digital services. I think historically you also have a very strong focus on wastewater, chemical process, compressed air technology and so on. You are a real expert in these areas. But now you also offer these digital services to your customers and develop them together in close exchange. This means that you offer not only industry-specific solutions, but also solutions for topics such as global machine park management. But you also increase energy efficiencies, availability and reliability of machines by means of artificial intelligence.

So you are quite broadly positioned, and now also with a consulting offer. That means you’re also helping other companies monetize their machine data and new business models. You are now a Business Consultant for IoT and Data Science. What specifically is the job of your department and what customers do you typically work with?

Florian

As an industrial engineer, I joined the company about a year ago and I’m responsible for expanding the consulting program. This stems from the fact that we have found that many smaller mechanical engineering companies in our industry are actually asking themselves similar questions over and over again – how relevant are digital services actually for me and my machines? How much will the development cost me? Where is the best place to start? What competencies do I need for this?

Quite a few questions that are always repeated. We have been able to solve these technical, but also financial and cultural challenges for ourselves over the last months and years, at least for the most part. Therefore, we now want to pass on this experience and help other mechanical engineering companies to find a starting point there from practical experience. To see to what extent data-based services make sense for their machines.

You’re the expert on Data Science. That means you’re in the business, too! Ricardo, your colleague, has already been a guest on the podcast. What has happened in the meantime? What developments are you seeing with your customers and what might have been added since then?

Florian

Let’s take another quick look at Aerzener Maschinenfabrik. After all, we concentrate as an application specialist in the oil-free conveying and compression of gases. Especially on rotary lobe blowers and screw compressors that we produce and sell. In automatic transport, for example, our machines are used to transport coffee from A to B using compressed air.

We have now also been operating our own digital unit for three years. Since the last podcast recording, we have expanded our team by several process engineers, statisticians, and programmers, and we have expanded our office space.

In recent months, we have used customer feedback from the first applications in the field to further develop our own platform. Also to leverage the machine data we’ve collected and analyzed since then to increase the predictive accuracy of our data models. Since then, we have really been in the process of gathering practical experience and developing it further and getting better at it.

As I said earlier, you also draw on the knowledge that comes from the parent company. But of course also with the platform, which continues to expand and is used by many customers.

Carl, I’m also interested, of course, how did you meet in the first place? This combination of a VGH insurer and a mechanical engineering company or digital unit is not exactly typical. How did that come about?

Carl

This is definitely a very exciting question! We actually met through this podcast. You just mentioned: Ricardo was on episode 33 here, and I’m personally a big podcast fan as well. I heard the episode with you and Ricardo and the sewage plant in Bad Pyrmont at the time. At the same time, we were looking at the topic of IoT at VGH. Then I just sent an email to Ricardo, and said this is a super exciting topic. It’s funny because we’re both on the same topic – actually, we should talk!

This cheers my heart! That’s exactly what the podcast format is also about: that it also reaches people who, like you, for example, are working on the very issues. Glad to hear that worked out!

Florian, how was it for you? You then picked up the ball?

Florian

Ricardo picked up the ball and made sure internally that we had an exchange with the team with VGH. We found out pretty quickly during the initial discussions that an insurance company can also be a stakeholder for the data-based services and the machine data that we offer and generate.

The nice thing is that we promptly identified a first plant in the field, which we retrofitted with our IoT solution on one side. And which, on the other hand, is also insured by VGH. This gave us a very practical and handy example that we could use to develop further ideas.

Carl, most listeners are probably interested now in what exactly you are doing in the area of IoT. Because VGH Versicherungen – you are the largest public insurer in Lower Saxony, you have 1.8 million private and corporate customers. You can read about it online. You have a range of property and personal insurance, 4600 employees, 400 VGH agencies and also 600 branch offices.

What’s particularly exciting is: What are you doing in terms of IoT and especially in industry? This is now a new topic for many.

Carl

I agree. It is perhaps a bit strange at first that VGH, as an insurer under public law, and then still regionally in Lower Saxony, is dealing with the topic of IoT. But like you said: We are a composite insurer. This means that we offer all lines of insurance, including industrial and, in fact, engineering insurance.

We are working on new topics on the market all the time. What potential does this offer our customers? What potential can we leverage for our customers and with them?

There is currently no getting around the topic of IoT. That is the reason why we have been focusing on this technology for a good two years now.

With regard to Aerzener Maschinenfabrik or Aerzener Digital Systems: What are the potentials that you have seen in this cooperation?

Carl

Perhaps by way of introduction: I work for VGH Versicherungen as a claims adjusterr. I mainly settle major technical claims. As a result of this activity, I noticed at some point that I often see the same manufacturers among my customers.

Many manufacturers look familiar to me. For example, I always walk past the Aerzen crates at sewage treatment plants and at some point I noticed that we always go to the same customers. And actually we also have exactly the same interests. Once the topic of customer satisfaction. And then also in the event of a claim, to serve the customer as quickly as possible.

If you want to put it a bit figuratively, Aerzen and VGH actually only drive to the customer with separate cars. Then came the idea: Actually, we should go there together!

Makes sense! So that I understand this correctly: Your job is, in the final analysis, to determine the damage that has occurred. Machine breakage or other – you drive out, verify, document?

Carl

Exactly, that’s actually the biggest part of my job as a claims adjuster. If damage has occurred somewhere, for example in a wastewater treatment plant, it is reported to us. My main task is then first of all to find out, is it a damage for the insurance? And, if so, in what amount we can settle the claim.

Florian, so if you’re going there by car as well, what exactly are you doing?

Florian

At this time of year, we encounter insurance there relatively rarely, because the machines from Aerzen are known in the market for their robustness and long service lives. However, with our predictive maintenance solution and digital services, we want to increase these uptimes and, above all, reliability.

However, if damage or a failure does occur and is emailed to us and the insurance company, we are interested in the causes of the failure. Then it is important to know: Was the machine properly operated and maintained? Or has it been left to wear and tear?

As part of our digital services, we can then, for example, record the load curves, read out error logs; simply track maintenance better. It is precisely this information that is ultimately of interest to a machinery insurer. I just got back into my car insurance late last year. I was also just offered this transponder again, which monitors my driving behavior, but gives me more attractive conditions in return if my driving behavior is good. It is precisely this potential that we also want to test for our machines through our cooperation with VGH.

Often the damage is probably not even caused by your machine directly, but in the upstream and downstream process. How was the machine operated? How did the operation go? – From that, it’s probably possible to draw conclusions about where the ecosystem comes together with insurance, right?

Florian

Exactly, definitely. It helps the insurance company that we can bring in the process, the domain knowledge. Often, when we encounter claims, it’s not just our machines that are overloaded and actively operated into wear. But there are also upstream or downstream processes where, for example, fog fan plates have become clogged in the wastewater treatment plants or similar, which increases the pressure and results in an overload of the machines.

Of course, without this process knowledge, claims settlement is also much more difficult. Finding the cause above all.

Which use case are we looking at in detail today?

Florian

In podcast episode 33, we already presented how we can reduce maintenance costs for sewage treatment plants with our remote monitoring. Today, together with Carl, we would like to show how we can also integrate key partners such as insurance companies with the right machine data. How digital services can therefore also be worthwhile for machine manufacturers and their customers.

However, we would also like to show what such a starting point might look like for mechanical engineering companies that are not yet optimally exploiting the potential of their machine data in this respect. Who may also be unsure whether they even have the right data already available to implement such business models.

I would also link the example of remote monitoring of maintenance costs again in the show notes. But today we really want to talk about insurance. The invitation is aimed at all listeners: Florian and Carl are available to answer questions. Network, either on LinkedIn or through me.

Challenges, potentials and status quo – This is what the use case looks like in practice [14:38]

Carl. You had said you guys are going out, there’s machine damage – what are the damage cases you see in the plant especially with machines and equipment at your customers?

Carl

I’ve found that’s always very segment-specific. As a composite insurer, we insure everything related to technology. Whether I have a mobile or standing or stationary machine.

Of course, we always have classics. These are operating errors, overvoltage or lightning damage. But not insignificant is actually the subject of wear and all that goes with it. In other words, anything of the kind that leads to premature wear of the machine. This may simply be a lack of maintenance, for example, or that the machine is permanently operated outside the operating points.

That’s a realization we made at some point, that in the stationary area, gradual damage – which you may not be able to detect at the beginning, but which spreads through the machine and abruptly leads to a standstill – is a big part of it.

If we go into this scenario a little bit. Suppose this damage has happened. In the event of failure, the customer faces really high losses. For the machine builder, but also for the operator. What are the biggest challenges your clients are seeing right now in these claims? And how does claims adjustment work today?

Carl

In fact, we still have a very traditional approach to claims adjustment. We receive the claim notification – that’s actually where it starts for us – classically by mail or via any calls or via e-mail.

By mail!

Carl

By mail, in fact. I think that’s always the first annoyance that comes up with many customers. After all, it can take two or three days for the mail to reach Hanover. During this time, a machine somewhere is at a standstill, and if necessary, sometimes in a critical infrastructure.

That costs real money!

Carl

That definitely costs real money. I often get claims reports that say “machine is broken” – that’s correct from the customer’s point of view. However, the insurance company cannot do anything with this statement. For me, the issue is, Why is it broken? What is the cause of damage? To draw conclusions as to whether this is an insured loss.

That’s a bit of the problem with us in claims. I always come when the horse has already bolted, so to speak. I would love to be there live for the damage. That would be ideal. Because then I could say exactly, all right, is insured or is not insured.

In other words, what happens afterwards is a major effort for me as a claims adjuster. I need to request information. I may have to go there myself. Involve an expert. I always notice when talking to customers: The customer actually only wants to know, can they already repair or order a new component or blower from Aerzener? And do we pay, and in what amount?

That’s a good tagline for this podcast: be there live at the damage. That’s exactly what IoT is now enabling. I record the data and respond immediately. After all, the biggest pain is that the machine is at standstill, the plant is at standstill – and that costs real money. And on the other hand, it just creates bureaucracy for you guys, right?

Carl

Yes, the most interesting thing is also: When we actually get into the cause of the damage, we often find with these wear damages that just such a very small component has triggered this damage. For example, a defective seal or bearing. But that triggers this huge process that causes costs and hassle for the customer – and of course costs for us.

Florian, which live data of the machines are relevant here? Perhaps using the example of rotary blowers.

Florian

Carl has already mentioned the example of bearings. In the context of damage prevention, we first look at classic variables of rotating systems: Vibration and acceleration data of the bearings, but also of the rotors used in our machines. In addition, we also record other data, such as system pressure, oil temperature, power consumption.

In addition, especially when we are not only talking about damage prevention, but also about reducing energy costs, we integrate weather data, such as temperature or air pressure, via an API, for example, so that we can make recommendations on how to reduce the machine’s energy requirements.

Our statisticians then use this data to train one or more algorithms in order to predict the probability of failure, for example, and then significantly reduce troubleshooting time and repair time in the event of a claim. Above all, also to avoid total failure by giving early warning – ideally up to fourteen days in advance.

If I want to tackle a project like this. Theoretically, we have the data at Aerzener Maschinenfabrik and Aerzen Digital Systems in this case. What does it take to really make that happen? What are the technical requirements that might come from you, or from stakeholders who are still involved, and are relevant for tackling an insurance project like this in the area of IoT?

Carl

I had just said: I would like to be there live when the damage occurs. That is actually the most important thing for me as a claims adjuster. To get the data, those at the time of damage, plus a certain time before. Because we have identified that the primary damage usually occurs some time in advance.

That means I don’t need live data at all. That is perhaps another important insight. We do not record all data of our customers 24/7. We do not have the capacity. But at the moment when the damage occurred, for example, Aerzen received the relevant data via their error logs.

I am an engineer. But nevertheless, the data must also be consolidated in a certain way. The claims adjuster needs to quickly see at a glance what happened to the machine? What are the most important parameters? What are the conclusions from this? Because I also – we are composite insurers: we have insured not only blowers, but also pumps. I am not a blower expert.

If you think about the whole thing on a larger scale, not just in the Aerzener use case, you can scale it – we don’t just have engineers with us, but also insurance sales agents. They also need to get on with the data and the evaluation logs and error logs. It must be understandable to such an extent and easy to get around.

And the very big challenge with us in insurance: we are a very old business. This has advantages. However, in terms of IT, this also has the major disadvantage that IT must also be adapted accordingly. That’s where we need to think about either building another interface into our legacy systems for Aerzen’s data. Or whether you plan the whole thing on a completely greenfield site and then think end-to-end.

You want to be live at the damage, but not with the live data. But have consolidated the relevant data, with error logs that report this damage in advance in the best case or just give you the info. You don’t need all the data for that. Instead, it is sufficient to record selected data for a specific case.

Carl

Exactly. That has to be in focus on the area, so to speak, on the relevant data. Because the sensors naturally produce vast amounts of data. As a claims adjuster, it is always important to make an accurate decision as quickly as possible. Especially for the customer – because they are waiting for me to decide whether they can start repairing.

The other issue is IT. I would argue that you are not the only ones with an old IT landscape, but probably also various customers. You hear it all the time: it’s a brownfield. There are systems running on old infrastructure, or not up-to-date. Not everything is always available at the beginning. I think there is a challenge on both sides to smooth out an IT infrastructure and make data available in the first place. Right, Florian? How do you see this working for your customers?

Florian

Yes, definitely. We have the opportunity there to offer interfaces through our own platform. For example, for VGH Versicherungen. Where then – as long as this is coordinated with the customer, of course – tailored fault reports can be made available, for example, in order to circumvent precisely this problem of connection in this triangle of insurance, plant operator and machine builder. And also to make this interface as meaningful as possible and fair and visible to all parties.

Interface means you build on existing infrastructure and still get the data.

Results, Business Models and Best Practices – How Success is Measured [23:57]

Carl, can you briefly explain the business case again from an insurance perspective? What opportunities are there in terms of cost savings or new sales?

Carl

You’ve already mentioned the two levers we’re working on. On the one hand, to actually tap into new customer groups, as we are striving to do with Aerzen. And the big next point is cost savings.

When I drive out – completely Lower Saxony – it causes immense costs, which is not insignificant in terms of sustainability and CO2 emissions. This two-pronged approach of more sales and lower costs in claims adjustment is what we are thinking about. And in regards to our customers: If we are more cost-efficient, we may also have the opportunity to offer more favorable premiums.

So other stakeholders are probably also exciting for you? Reinsurance and other partners? After all, that’s an entire ecosystem that you need and build.

Carl

Definitely. After all, we don’t just have our reinsurers. In the event of a claim, for example, we also have to pay the experts who drive out to the site in addition to the claim – and whom the customer pays again later through his premiums. Of course, there is great potential for savings there, too.

Florian, what is the business case for you?

Florian

We are of course following Carl’s argumentation and want to increase the attractiveness and the concrete benefit for the users of our machines and the associated services through cooperation with partners such as VGH Versicherungen, for example. In addition, we see very fundamentally the savings that come with our condition monitoring system or energy management.

The training of the data just mentioned allows the predictions of the critical wear point up to fourteen days in advance. And also the so-called Mean Time to Identify, i.e. the time to detect the error is reduced to zero at the point. Because I can see directly where a defect has occurred on the machine.

In addition, repair time is significantly reduced because there is no need for a service technician to drive out, diagnose, drive back and evaluate the whole thing. Instead, they can view the whole thing remotely and draw a conclusion much faster. For example, we took a look at a cement plant. There, we can reduce unplanned downtime costs by just under 5,000 euros per machine annually thanks to real-time fault detection and failure detection.

The beauty of this is that the machine data used as part of this savings is also relevant to the applications Carl describes.

That’s really nice to see that you have a concrete business case there. This is also directed at all mechanical engineers out there: This is a potential that can be used very well and leveraged together with you. Really exciting!

Carl, towards the future: what is the topc, what will it develop into? That’s one of the main things you have to think about: how can you leverage the added value of the data in the future? What trends are you seeing? What’s in store for us?

Carl

I actually see that with this use case, we’re mapping two big trends that are forming in the insurance industry or landscape right now.

This is the issue of risk prevention. That the insurer is much more involved in risk prevention. In other words, not just leaving risk prevention or loss prevention to the customer, or quasi obligating the customer via any obligations. But actively participates there. Because in the end, they also have their own interest in having little damage.

Another trend is that the types of claims are changing. I come from a very classic property insurance background. I always need, as it says so nicely in our terms, damage or destruction of a thing. My predecessor always said the axe has to be in.

But in the case of Aerzen, or in the case of the IoT kit, for example, it could be that I no longer suffer any property damage at all. But that I only suffer some kind of damage – for example, property damage or product liability damage. If, for example, the promise of performance is not fulfilled, for whatever reason, from the insurance company’s point of view I do not have a classic property damage – but nevertheless I have a damage for which the insurance company has to pay.

And the risk prevention … these are really like some kind of new bundles that you guys are developing. You know it from the private environment. In the future, they will have a machine with an IoT bundle and say that if the prerequisites are met, you, dear machine builder, will actually no longer have any downtimes, because we will monitor it, and on the other hand, we can make you a certain offer.

Carl

Exactly, that’s the direction it’s going. We also looked at the issue of premium reduction. In this use case, however, we found that the premiums for the machines we are now talking about with Aerzen are so low … or in a range that we no longer have any leeway. In this context, the issue of risk or premium reduction plays a rather subordinate role.

Yes, you said at the beginning that there are different areas and segments in which you are active. That’s only part of it. There are quite a few other machine builders out there who may have other use cases, with other models behind them.

Florian, do you have any experience from the project in how you approached it together? Can you share something? I’m always asked about best practices.

Florian

Absolutely. At the beginning of the development of our data-based service, we mainly focused on the users internally, i.e. our service and sales staff, but also on the external customers, the plant operators and users. From our point of view, it is important to ask who else can benefit from this machine data and how these players, for example insurance companies, can also be integrated into such a business model in a way that adds as much value as possible.

In this case, as already indicated, we can offer added value, for example, by generating tailored error reports that make insurance premiums more attractive to users. Or by managing to increase confidence in our predictive maintenance solutions via a performance guarantee that is secured by a VGH, for example.

Carl, can you also share best practices from your perspective?

Carl

My takeaway from the case is that we need to think much more collaboratively. You said it at the beginning: Actually, it is not very obvious that an Aerzen machine factory cooperates with a regional insurer from Hanover. But if you take a second look, you can see we’re both going to the same customers. And simply talking to each other and finding ways … I had already hinted at this with the topic of dynamic pricing. This is the path we have taken.

At some point, however, we also realized that this was not going to get us anywhere. Then also honestly, transparently saying to both sides, we’re not pursuing this path any further – those are my two big experiences that I’ve had in this case.

Solutions, offerings and services – A look at the technologies used [31:47]

When we get into the doing. Suppose I find that exciting now and say that’s exactly the subject. But now it is also the case that many machine and plant manufacturers … In our network, a great many are innovative, think along these lines and so on. However, there are also studies that say, for example, that of 250 companies surveyed with over 100 employees, only 29 percent are working on IoT projects at all.

Florian, from your perspective, what’s stopping these companies from doing the same thing that you guys have done? Both internally and then, of course, to implement the whole thing on the market?

Florian

That’s totally exciting, Madeleine. On the one hand, we hear in almost every podcast of yours, but also in this one, what added values data-driven services can have for engineering companies and their customers. Especially in the area of efficiency optimization, energy cost reduction, increased availability, additional revenues, etc. There are many possible advantages, depending on the industry application.

In practice, however, nine out of ten German mechanical engineering companies have internal implementation problems. This starts with reservations within the organization. According to the motto, “Yes, but our machines are selling well, they’re still running! Why should I deal with such new topics?” It starts with unclear responsibilities. Because there is not inherently “the one” IoT department. And it’s not a pure IT task, either. It’s a cross-sectional function that affects all areas. And it also goes very specifically to a lack of business model and knowledge, especially in the area of data analysis and programming. That makes implementation more difficult.

Particularly in the case of smaller mechanical engineering companies, it is often the case that we do not only perceive questions along the lines of “How long will it actually take? When will it pay for itself? What resources do I need for this?” Rather, full order books mean that we don’t really see the need to deal with this on a broad scale. Time is then spent more on keeping day-to-day business running.

As you can see, the market is moving relatively fast. The topic of competitiveness is also one of the biggest where you should stay on the ball!

You just mentioned the organizational side. Is that such a major issue, that it’s about accountability when you’re trying to get these things out on the street? Or how do you deal with it in terms of the organizational part for implementation within a machine and plant builder?

Florian

First of all, this is a very important foundation that we had to learn ourselves, have learned and now want to pass on to other mechanical engineering companies. We first get all the relevant departments together to make it clear that this is not just a development or IT project and that, from our experience, you can only be successful if you really get from the workbench, through sales processing, to commissioning, and think in terms of after sales.

Very simple example: If the installer has to install the gateway, but there perhaps the work step takes twice as long or they make mistakes because the instructions are not described correctly, that is something that significantly increases costs and lead times. The processor in the service must also be able to cast this digital service somewhere into a quotation and order form.

These are all such small details that have to be right and where everyone has to know their role so that the whole thing is performant and reasonable for the customer. Most employees come from a decades-long expert position that they don’t want to lose, but have to give up to some extent – or at least expand their knowledge.

There, with our own implementation experience for our machines, we have quite a high credibility and acceptance for a neutral moderation. This allows us to get these colleagues on board first and jointly develop a target image of what a machine could look like in the future with reference to data-based services. And what contribution, above all, each department can make.

You have been on the market for several years and have also supported other machine builders. How are you dealing with this challenge and how are you specifically helping the mechanical engineers now? What does such a path look like? Let’s say someone inquires and wants to implement this.

Florian

First of all, it depends on how the mechanical engineering company is positioned. Particularly when it comes to finding a starting point in the first place, this is precisely the bringing together of the departments that I mentioned. Discuss the ideas together, and also the respective roles of the departments, under neutral moderation.

In addition, we also want to teach the basics of business model development, for example. So that the companies are able to build up the knowledge, to deal with this topic independently and also in a structured way, and to look at what is worthwhile for us and our customers?

Here, we have the advantage that, as a mechanical engineering company, we are quite close to the industry. And not only bring the methodological knowledge, but often be able to dive in individually.

I think it’s also relevant that you don’t just go along with it in terms of the business model. But often it is also – we just had it – an IT issue. That is, you also accompany to record machine data. But also, with your department, with your background, in analytics. You will accompany from the business model the first start up to the recording and processing of the data. And then with ecosystem partners, such as VGH Versicherungen here, you also address such topics – you are relatively broadly based and offer the whole thing end-to-end.

Florian

Exactly. The business model idea only provides the direction in which we want to move. We then look to see if we can work with existing sensor technology to capture machine data relevant to the business model. Or whether data that is not available in machine control and the like – such as pressure, temperature, speed – can then perhaps also be recorded.

Then we take our customers by the hand, sift through this machine data, look at the data quality and, above all, evaluate whether it would make sense to build up internal competencies to evaluate this data and develop data models. Or whether there might be a need for a third partner who specializes in this kind of thing.

At this point once again the call: Who is interested – feel free to contact us! Florian and Carl, is there another message you would like to give to our listeners?

Florian

I would again focus on the machine data, which has a certain benefit not only internally for sales, service and the development department. But also for third-party companies beyond the machine users, such as insurance companies.

We can only recommend to every machine building company that is involved in the development of data-based services: Look at who else can benefit from this machine data? How can these companies be integrated into the business model in the most profitable way? If you have ideas there but are unsure how to get started, feel free to contact us. We have developed and implemented such digital solutions for our machines ourselves. We pass on this experience in a pragmatic and practice-oriented manner so that other companies can also find and develop a good starting point and, above all, applicable solutions.

Carl

My message is perhaps a little more general: to simply dare. The thing we did with the Aerzeners … just dare to do it. An insurance company, a completely different industry … Thinking outside the box and making it easy. As we have seen with the Aerzeners: Suddenly opportunities arise that we can both make use of together. This is then a great experience!

Yes, perfectly! It is also important to trust each other and have partners at eye level, where you can develop the whole thing together. Because I don’t think that’s where it stops at the point that we’re talking about. I’m curious – if we do the recording again in five years, we’ll probably be quite a bit further along.