This episode is about the collaboration between the global leader in fluid engineering Sulzer and Innomotics that are now opening up a new era for large pump operations. By combining their BLUE BOX™ and SIDRIVE IQ IoT platforms and services, the two companies will deliver a new integrated solution that improves equipment reliability and reduces operating costs.

Podcast episode summary

Pump operators traditionally focus on four main business drivers:

- ensuring availability and uptime

- enabling risk-based maintenance for reliability

- optimizing throughput for performance

- minimizing LCC and CO2 footprints for efficiency

In order to effectively shift from preventive maintenance to predictive or condition-based maintenance, it is not enough to solely focus on the pumps, as mentioned in the podcast.

A more sophisticated approach is needed, one that leverages Digital Solutions, IoT, and AI. This approach, termed by Sulzer and Innomotics as data-driven decision support, uses a digital pump monitoring and analytics platform and expert support to translate analytics findings into tangible business value for the customer.

In our jubilee episode Dr. Marc Heggemann, Head Digital Solutions Sulzer Services, gives us insights about the benefits of the partnership with Innomotics. Sebastian Winkler von Mohrenfels, Vice President of Digitalization & Software at Innomotics, shows us insights about the integration and exchange of data between Sulzer and Innomotics IoT platforms.

How this cooperation contributes to reducing the carbon footprint and how you can become part of this journey – you can find out in this episode!

Episode 100 at a glance (and click):

- [11:19] Challenges, potentials and status quo – This is what the use case looks like in practice

- [23:50] Solutions, offerings and services – A look at the technologies used

- [34:00] Results, Business Models and Best Practices – How Success is Measured

Under the name Innomotics, Siemens is combining its business activities in the areas of low- to high-voltage motors, geared motors, medium-voltage converters and motor spindles and is forming a new, leading motors and large drives company. The portfolio includes an innovative solutions and digitalization portfolio and a broad range of service offerings. The related businesses were previously assigned to the units Large Drives Applications and Digital Industries and to the legally separate Siemens companies Sykatec and Weiss Spindeltechnologie.

Podcast interview

This episode is about the collaboration between the global leader in fluid engineering SULZER and Innomotics who are now opening up a new area for large pump operations by combining their BLUE BOX™ and SIDRIVE IQ IoT platforms and services. The two companies will deliver a new integrated solution that improves equipment reliability and reduces operation costs. Today, Dr. Marc Heggemann, Head of Group Digital Solutions SULZER, gives us insights about the benefits of this partnership and Sebastian, Vice President of Digitalization and Software at Innomotics, talks about the integration and exchange of data between SULZER’s and Innomotics’ IoT platforms. How this collaboration contributes to reducing the carbon footprint and how you could actually become part of this journey, you can find out now. This is a super, super, super special episode because this is our 100th episode! We are so happy to have been able to inspire you with the latest developments in Industrial Internet of Things and exciting use cases for already 100 episodes. I would like to take this opportunity to thank you for your support and interest in our podcast. Here’s to the next 100 episodes!

First of all, hello Sebastian and hello Marc. It’s nice to have you today and welcome to the IoT Use Case Podcast. Sebastian, I will start with you. How are you today? And where are you at the moment?

Sebastian

Well, I’m pretty well and I’m in Nuremberg at this time, in the office.

Nürnberg? Okay, great. So Nürnberg is the place for Innomotics, right? Next to Erlangen?

Sebastian

Yeah, it’s one of the many places we are. It’s a global company, but in Germany it’s one of the main locations.

Great to have you today. I’m really happy that you joined. Marc you are with us today too. It’s nice to have you. Where are you today and how are you at the moment?

Marc

I’m doing great and I’m in Winterthur at SULZER head office in sunny Switzerland.

Switzerland, right? I really need to check up on your location there. It must be beautiful, right?

Marc

It is, it is.

Great. Maybe we could just start right away and briefly introduce Innomotics and show your business model regarding IoT. Sebastian, I would start with you. I mean, Innomotics, is best known as a world leading manufacturer of motors and converters. And, of course, you are the inventor of the dynamo machine and your products are the base for drive systems for a wide range of industries and applications. And you are the Vice President of Digitalization & Software at Innomotics. Could you give us an insight? What exactly does your department do and what kind of customers do you work with?

Sebastian

Yeah, Madeleine, that’s true. We are a true mover of the industrial world, the real green motion company you would probably say today.

Our customers are across all the key industries from oil and gas, infrastructure industries like mining, power generation, but also chemicals, food and beverage. So the list is quite long. And our business is actually mainly motors and drives. Mainly medium voltage and high voltage motors and drives, solutions and coding services for these. And that’s typically products in a range of hundreds of kilowatts for the motors or more.

For the experts in the audience, maybe 180 kilowatt ampere for the drives or more. My team is basically responsible for software and data. We have set up globally across the main continents, of course. So we do have hubs in Germany, US, India and China. And our mission is practically IoT/Internet of Things and embedded software for our drive systems solutions and services.

Great. So I would love to learn more about that because here in the podcast, I, as you might know, I always talk about real-world use cases from the practical side. Sebastian, could you give us an overview what kind of use cases you’re addressing with your IoT portfolio and which kind of projects we are looking at in detail today?

Sebastian

In our markets and for our customers, there’s plenty of use cases they really care about. And they range from availability, over serviceability, energy performance, productivity. I mean, you name it, the list of buzzwords is long and sometimes they even overlap. But you mostly find a long list of these.

And from an IoT perspective and as the market leader in motors and drives, of course, we do care about these. I mean, it’s a big opportunity. And as you understand, and I think it becomes quite clear in your podcast series, is that many of the use cases cannot be served by the product itself. So there is, of course, a need for more. And that’s in our case, IoT.

And that’s why we try to answer that challenge or that need for the customers with our SIDRIVE IQ platform. That’s basically our way for smart fleet management of motors and drives or drive system solutions. And for that, we also try to address the main use cases of really which matter for our customers. I think some of them we already solved quite well. I think Mark will talk about that later in the podcast. Others, I think we have already presented like a year ago here in your podcast series with Threedy and 4soft, for example, on 3D data visualization.

Yeah, great podcast, by the way. I will link that in the shownotes.

Sebastian

Today, it’s of course mainly about how we best collaborate in an ecosystem because it’s key to not do things on your own if you want to be successful and create value. In a world which is quite complex as of today, this gets more and more critical to really make a difference.

Yes, that’s true. And I would love to learn more about how SIDRIVE IQ as a platform is working. You brought Marc today as I guess a partner and a customer, maybe at the same time. So how did you guys get know each other? Is that a classical sales connection or is there a personal connection?

Sebastian

So I think it’s quite some time ago, and Marc has probably a good story about that. I think we met over a customer, right Marc?

Marc

Yes, I think this was mainly customer-driven a few years ago. Both Innomotics and SULZER have and had digitally enhanced offerings in the market. Innomotics focusing on the drives, SULZER focusing on the pump trains. Customers are interested in ideally one holistic solution for all their assets, which we can understand. So the customer said to us, you guys, Innomotics and SULZER, make me an integrated offer. This is how it started.

The reason why SULZER had and has a pump-specific and AI-based offering and not a holistic one. It needs to be meaningful and it needs to be really relevant for the customer that you have the right outcome. So holistic solutions can handle all assets. However, often these struggle to have the required accuracy for the customer. Customers, for example, don’t like false positives or false red flags. To provide one single solution the proven asset specific solutions join forces in an ecosystem, as we do with Siemens SIDRIVE IQ and SULZER BLUE BOX™.

Yeah, great. You are leveraging your joint activities now to a new offer to create value for end customers. Marc, you just mentioned pumps. Of course, SULZER is a global leader for fluid engineering. You are known for pumps, energy, water, and other industry and related services, for example. And these pumps can leverage Siemens motors and drives. SULZER has been headquartered in Zurich since 1834. What’s really interesting is your vision regarding digitalization. Could you give us some insights?

Marc

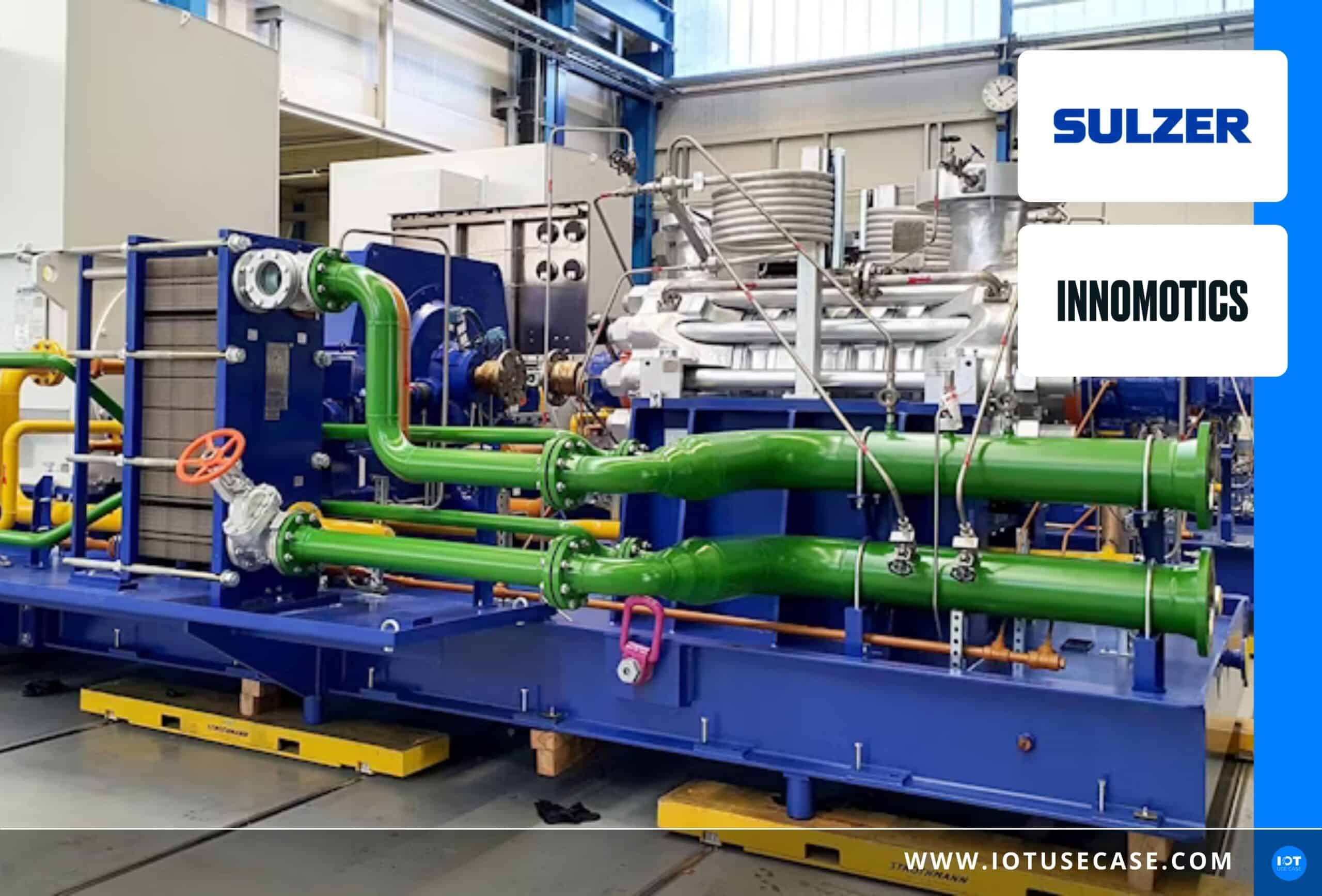

As you mentioned, SULZER is the leader in fluid engineering solutions, pumping solutions amongst others. The addressed markets are very similar to what we have with Innomotics. The energy market, power generation, water, mining. Everywhere where you have big pumps with big drives SULZER customers benefit from our commitment to innovation, to emphasize one beyond performance, quality and our global responsive network of over 180 world-class manufacturing facilities and service centers.

With the race of IoT and AI, it has been a logical next step to make “digital” a part of our strategy at SULZER, to use these new technologies to add more value to our customers and partners and also to SULZER. Digital, IoT and AI are no end in itself. These rather improve existing services and empower new types of services including service agreements with and for customers.

For example, customers better know which pumps are at risk or what energy or CO2 saving potential their applications have or SULZER helps to reduce customers’ risks with performance or flat fee contracts. In a nutshell, you can say digital, IoT and AI are key to position us and differentiate us also as a leader in the next generation pump technology and services.

These pumps are huge, right? So do you have some examples where you can find them in the industry?

Marc

Yes, these pumps are in applications, for example in big power plants, boiler feed pumps. So these pumps are typically in the hundreds of megawatts or in the hundreds of kilowatts and so these pumps are huge and so there’s a lot of value which you can create for the customer and you can help customers a lot in these areas.

You can join our monthly monthly network activities around the IoT Use Case Podcast. If you have questions or common starting points with Marc or Sebastian, I will link their LinkedIn profiles in the shownotes.

Challenges, potentials and status quo – This is what the use case looks like in practice [11:19]

Marc, I would love to learn more about the challenge because you already talked about the service agreements, insights about which kind of pumps are at risk risks and performance criteria. Could you please give us an insight what the challenge for your customer is and what kind of potentials you have noticed in these processes?

Marc

Sure, I’d like to give you a concrete customer example to make it really concrete and tangible. Pump operators have mainly four main business drivers. So first is availability. Pump operators want to avoid unplanned outages and ensure uptime. Second is reliability, increase meantime between repairs and also enable risk-based maintenance. The third one is then performance, optimized throughput. Often more throughput means more money. And the fourth one is efficiency, and this is an emerging one because it’s not only minimizing life cycle costs, but it’s also for minimizing CO2 footprints.

This is an emerging driver in the last couple of months and years. And you cannot quantify, for example, saving potentials and identify pumps at risk when you just look at these pumps. You need to do more when you want to go from preventive, this means scheduled maintenance to predictive, condition-based maintenance. For example: you don’t want to bring your car to maintenance based on a yearly schedule. You want maintenance based on sensor data when maintenance is really needed. So that’s the next level of doing maintenance for your equipment.

Sebastian

I think Marc summarized well a very good set of the key challenges. But we should never forget that in many industries, challenges often start with very simple things. So, if we call something availability or prevention of downtime, these things often already fail when it comes to availability of information to deal with the situation. Things like documentation, manual access, understanding the code on the HMI panel. Knowing what the PLC is saying, having the competence to deal with the codes know what it means, etc.

The chain is typically quite long and the use cases and challenges summarize that very nicely. But of course, it’s quite heterogeneous, multi-shaded. The other major thing I would like to add is, and I think Marc touched on that in the last challenge he mentioned, is the big sustainability challenge. I think efficiency almost cuts it short. Of course, if you call it sustainability, there’s many more things beyond CO2 footprint that really matter more and more to the customers.

Especially in our industries, process industries, efficiency and CO2 footprint are quite critical at this and drive many customers to also do investments, for example, into new technologies like ours to really help them along the way towards a net zero footprint.

It’s also about making better decision based on the condition and the benefit for a more effective service support. Marc, could you give us an insight what the typical day in service work looks like? What kind of customer requests are coming in and what are the processes?

Marc

Yes, sure. We can help customers with digital solutions, IoT, AI, to optimize their operations and maintenance of their critical pumps, of their critical equipment. We call it data-driven decision support. We create the customer value leveraging two main elements. On the one hand, we have the state of the art digital pump monitoring and analytics solution. However, we don’t leave the customer alone with the software. We also provide them the expert support to then turn the analytic insights into customer value in the end, into actions.

This is the key. Customers, pump operators are very busy with all kinds of tasks. That’s why we make it as easy as possible to really translate the digital findings into actions that the pump operator has to do as a next step to keep the pumps up and running, to keep them efficient and to keep the lights on.

Yeah, great. Could you tell us more about the relevant data for different of these customer projects, because you talked about data-driven decision support. And what kind of data is relevant to do that?

Marc

Yes, so to start with, we just need six parameters. We call it performance data. It’s the flow, suction pressure, discharge pressure of the pump, the input power, the speed of the pump and the fluid density.

And that’s all that’s needed to get started. And if customers have more data, we can take it and analyze it too to have an even deeper analysis on the data for deeper insights. This way we can then help to really ensure the availability by identifying pre-failure conditions early. With regard to reliability we can quantify the lifetime consumption of pumps to better plan maintenance.

Regarding performance we can identify bottlenecks in the pump system. If you have a series of a larger set of pumps, you might encounter a situation where one pump acts as a bottleneck. You want to know which one it is. The sustainability driver, energy efficiency. We can quantify both the energy costs on the one hand, in terms of saving potential, but also the CO2, which can be saved.

And Sebastian from Innomotics’ point of view. What kind of large drive data is relevant for you in this project?

Sebastian

Quite complementary, as you understand the pump is the load for the drive or the motor. It’s eventually one system from a customer’s perspective. And that’s also the main reason why the combined set of information data is so important, because it’s from the customer perspective, it’s explanatory for the entire unit. It would help them to make better decisions on the entire pump application.

From the drive or motors point of view, it’s a similar set of technical KPIs like temperatures, like currents, like vibrations on the mechanical parts. From the drive, for example, which is an automated system, you would also have log, sort of registries for how the drive is doing, like in a computer. You look at switching cycles of the drive, how we’re switching the currents and so on and so on. At the same time you have static information which is not measured information but let’s say information which is like a nameplate to the particular product.

Like with the car you have a license plate, you have certain parameters listed to that license plate like the type of the car, like the rate of performance it can drive. You have rated information on the performance capabilities, you have serial numbers, all these things, which do matter sometimes if you do assess the system. And I think that’s also the critical or the important element of meshing things together. Because again, if you look at these all together and you have an incident like Marc described, it can be very helpful to not only have the pump and its parameters measured or static, but also to have the other components because a particular incident can come from many places. And sometimes if you only have part of the information, you don’t see where it comes from, maybe the location where the actual issue comes from is not visible to you.

Thanks for all these explanations because I guess these kind of data types help to understand what kind of data I need. One last question about the requirements, because what’s always important for customer are different technological requirements. Marc, could you give us an insight what is relevant for your customers to set up these kinds of solutions right now?

Marc

If I have to name one, the secure exchange of data is of utmost importance. Also data exchange needs to be easy and allow for clear demarcation to protect customer data and also to demarcate each other’s data and IP and the use of so-called API’s, application programming interfaces, or little software programs, which are particular suitable to do so. An API is a way two or more parties can talk to each other in a secure manner. And so this serves the requirement on data security. For customers, our digital solution is easy to deploy and run securely in leading browsers like Edge or Chrome, so there is no need to install additional software.

I think that’s pretty important for, for many companies out there that your solution is kind of fitting various relevant technological requirements.

Marc

I have one point to add on this one, because we talk about the collaboration between Innomotics and SULZER. And one important element here is that we also bring this to the next level now in the collaboration, because we go one step beyond and now integrate drive health KPI to start with into the SULZER BLUE BOX™ solution. Now customers can see all the key business information in one place. We started with this one KPI, and this is the first one of more to come. We also want to do that in customer co-creation.

To the audicence: if you are a pump operator, you are interested in this kind of application, possibly add value also to your application, maybe in a joint manner. We would be happy to have a discussion with you about what’s especially important for you in terms of having a digital solution, a platform, a service, which could make a difference for you. We would be happy to have a discussion with you to possibly co-create something together.

Thank you for this approach. And I guess maybe it’s interesting to talk with pump related companies or companies with large drives. It could be interesting to talk with everybody who’s thinking about these kinds of new services now, right?

Sebastian

Yeah. And I think Marc is hitting the nail on the head in a way that for customers, it’s all about reducing the complexity. To handle this kind of complexity they are already facing. The key requirement for that is to be part of the solution to reduce that complexity for the customers because that’s where value creation starts. If you offer something of value, you want to make it as easy as possible and consumable and usable for your target customer to make benefits out of that. And I think that’s what we’re trying to get here. And much of this goes in co-creation. And other things may go in a more incremental long-term way, they evolve over time through experience and traction.

Solutions, offerings and services – A look at the technologies used [23:50]

To come to your concrete solution, you have built together. Marc, could you present your solution in two or three sentences in a tangible way? Without getting into the technological details? What did you do exactly? How does the solution look like today?

Marc

In a nutshell, we can say we bring two individual solutions together, that we integrate the findings of the Siemens solution of SIDRIVE IQ into the SULZER BLUE BOX™ application. And as earlier mentioned, we start with one KPI, it’s a drive health KPI, which comes out of SIDRIVE IQ, which you can also see now in the SULZER BLUE BOX™ solution, which is the first step to have all the key business information in one place.

And we want to expand on this, and we want to do this in co-creation because it’s important that we develop the right things which are most relevant to our customers, to pump operators.

Sebastian

Right, eventually in catchy statements for the elevator speech for the CEO. Our operators will have an improved, maybe more integrated asset management capability for these pump applications. They should have better coordination of the experts, which Marc mentioned earlier, who work on the data.

And maybe, and hopefully do also have a much better orchestration of actual actions they have to take in order to make changes in the real world. Because of course only data and digital will mostly never change the reality as such. And if there is something to be done, it should be the right thing, in the right time and in the right form. And I think that’s eventually the desired and targeted outcome this kind of integration is providing.

Yes, maybe to understand that in a more deeper way, I would love to ask three questions about the solution itself. You told us about specific data like flow pressure, fluid density, or even temperatures. How are these kinds of data types collected and processed by your hardware. So how does the data collection work in the first step?

Sebastian

Yeah, so the data collection is done or can be done at several points for this. There’s a sort of BLUE BOX™ side where data collection is carried out but this is done mostly without any hardware and in an IT layer from the customers. SIDRIVE IQ itself also does collect data from the field. That means it’s possible to acquire information directly from the drive system itself, which gives possibly higher resolution in some of the data points and also more expanded data sets for the asset. And at the same time SIDRIVE IQ can also collect data in an IT layer. But these two data collection streams are there in order to be further processed in the later chain of value creation.

Marc

To add to this point, the SULZER BLUE BOX™ solution doesn’t necessarily need any hardware as you also mentioned Sebastian. Customers securely send their pump train relevant data one way to us in a secure manner to the secure SULZER Cloud. This is one way of doing this. Alternatively, customers can also securely send data through the Siemens SIDRIVE IQ Edge device. So, we have flexibility here and we give customers options. Whatever is easier for the customer, we can do. And this is also important in digital solutions that you make it as easy as possible for the customer and provide options to customers to engage with you.

Okay. So you kind of have two opportunities. Using the Siemens framework and this solution, or you use the SULZER platform. How does this data processing to send the data securely in the cloud work? Marc, could you give some insights to that?

Marc

Sure, SULZER uses Microsoft Secure Cloud that is trusted across industries ensuring the data is secure. And we believe Microsoft can afford everything and they will do everything to keep it state of the art and secure because this is their business model.

Sebastian how does it work on your on your side then?

Sebastian

The probably not so glossy answer is that many people have to really work hard in order to ensure this kind of security and build all these data workflows, maintain the infrastructures and all these kinds of things. And of course, also on the SIDRIVE IQ side, and the same on the BLUE BOX™ side. It happens a lot. And I think on the SIDRIVE IQ side, maybe the additional distinction is that we do have a certification for cybersecurity standards, which is ISO 27001. Because of course, we take it quite seriously how data and information of customers are managed and handled.

We want to do best and state of the art of whatever can be done in order to treat that according to confidentiality and protection, and make sure besides the value creation we’re actually looking for, everything else is consistent and with full integrity. The data processing itself of course is all done in cloud infrastructures, it’s cloud-native infrastructures with a lot of open source, the different speeds of how data is saved and I think quite some say, meshing in the process of different value creation steps on what happens to a measured sensor value down to what actually is the interesting thing – the transformation into a value within information which someone else can use or system can.

I would love to learn more about this data analysis part, because you talked in the very beginning about the business case of your customer. It’s for example, to improve planning the maintenance activities or to find the bottleneck. How do you do this data analysis part on this concrete data? Could you give us some insights to that?

Marc

So as mentioned earlier, data analysis needs to be meaningful and relevant for customers and not just show red and green data. This means, for example, we leverage AI machine learning using hybrid physical numerical models. This means we not only use statistics, but we also integrated our pump OEM engineering knowledge into the code to improve the accuracy. The target is always to quantify KPI’s describing the health, performance and efficiency of pump trains and systems. And as mentioned this needs to be meaningful and relevant in terms of insights for the customer.

Sebastian

Yeah, maybe I can add for the clarity on this co-integration. The data analysis part is happening at least at two pillars or layers, one in BLUE BOX™ and one in SIDRIVE IQ. And similar to the BLUE BOX™ side as Marc described, on SIDRIVE IQ side also, there’s at least three pillars on how AI is done, which is automation of domain knowledge, which is proprietary, like in SULZER’s case, to the OEMs making the particular product.

It’s about numerical modeling, which also is proprietary knowledge, which is already in these OEMs. And it’s also about machine learning and only all these together typically can yield some meaningful output, as Marc mentioned.

And one reason for that is that in many industrial use cases, the data richness is not that vast. So that means the word big data is in that form a challenge that for many cases to really apply a full machine learning or pure machine learning approach, there is a lot of limitations for meaningful outputs at this point.

That’s why it’s so essential to take all the three angles and bring them together to deliver robust outputs for information a user or system can use. In our case here, the starting point, as Marc mentioned earlier, is the health grade, which we deliver into BLUE BOX™ from SIDRIVE IQ. The health grade is a score, which is derived from these three pillars I just described, which describes the health, for example, of a drive and does come with further prescriptive information or recommendations in case the health grade is going from a green state to a yellow or red state.

Like when you go to a doctor, when you’re healthy, everything is okay. If you’re a little sick, then you look at blood values and all these kinds of details and you get a recommendation what to do, maybe a prescription. That’s very similar from the logic here.

Yeah. And that’s why I love this constellation with SULZER and Innomotics here, because you really know your drives and of course, the pumps and you have the insights to all these data to create value out of that. It’s great to have two partners here who are really insightful about the data, which is then meaningful for the impact for the customer in the end.

Results, Business Models and Best Practices – How Success is Measured [34:00]

I would love to sum up this episode with the business case because we started in the very first one to talk about the challenges of the customers to make better decisions and effective customer support. Can you sum up the business case for the customer?

Sebastian

I think the short answer is productivity for the customers in the value chain. We integrate things which saves a lot of money for ourselves because it’s impossible to work in all the blind spots on a particular physical assets because of the lack of competence, time, resources, and so on. And at the same time, it’s about productivity for the customer because if we do that and we speed up the entire value creation with the data.

This eventually is resulting in the impact we were mentioning in the challenges the customer is having. For example, availability, reducing the downtime. If an integration of data produces a better result in a shorter time, with a clear actionable output, then this is about real plain money on the table for the customers. And our customers have operating downtime costs between 50,000 to a few million euros a day. that is quite serious money.

Marc

The business case for the customer is on the one hand to save life cycle costs or to reduce the CO2 footprint. Customers want to earn more money, if possible. So if we can help here, that’s another driver in terms of business case. And also customers pump operators want to mitigate operational risk. This goes also along with greater peace of mind which shouldn’t be undervalued.

With this created customer value, companies like Innomotics and SULZER also earned the right to capture some value as well. It’s important to add value to everyone in the value chain. And then it makes sense for everyone and it’s sustainable for all.

Industrial IoT is about creating great partnerships, to bring all these expertise together and create these win/win/win situations for the end customer for system integrators, but also for different, partners. Do you have conclusions for the end, some experiences you would like to share? You were addressing this co-creation approach earlier: Do you have any experience for the first customer talks you have on this on this project here?

Marc

So in terms of creating mutual success, I would say it needs three main elements. So first is customer focus, really focusing on the customer. This is key, developing the right things, having the right solutions for the customer. Then in terms of collaboration with the customer, but also between Innomotics and SULZER, trust in each other is key here.

And the third one is keeping it easy. Build something of value quickly and grow from there. Don’t shoot for the pie in the sky. Look for first value and make it happen. Then you can demonstrate value and then you can grow. You justify to grow.

Sebastian

I think I would agree with the customer and business focus. Imaybe would add three more topics to the list. I think number one is there is some need of trust to dare certain things. And I say that because many of our industry are still conservative and Industrial IoT is still not the main line. It’s not very accessible to many. And sometimes this requires just this kind of courage to really do and also look at opportunities, like we have here with this kind of collaboration, co-creation.

The second I’d like to add is the mindset of an explorer because in some fields there are some new things and It’s not so easy to overcome them sometimes. Be it for cultural things, be it for let’s say sake of argument and convincing, or be it for the fact that maybe in certain industries, certain things have been done the same way for years or decades and so changing something, changing a running system, is not easy. The running system runs because it runs well.

And then the last point is, I think, the persistency to really also get things done. And as Marc said, sometimes things start small and sometimes small things seem to be negligible. They don’t seem to be exciting enough to be shown. And I think that’s exactly the moment where there is the persistency needed because big things normally grow out of small things. Big don’t just fall from the sky, and that’s why it sometimes requires to really go all the way and keep the resilience up to make things happen.

Yeah. So thanks for sharing these six kind of key elements you see mutual to success for these kind of projects with customers. I would love to sum up the podcast and thank you first of all, for these insights. That’s a really great solution around the data driven decision support. You described pretty well what kind of data is relevant and not just only from the pump perspective but also from the drive’s perspective. What kind of data is necessary and what the value for the customer is in the end. We had talked about different use cases all in all to create the key value for the customer. And thank you for sharing these insights. It’s not commonplace to be that open and to ask you for co-creation with the customer and that’s a great thing to do. And I’m really curious to see where the project and the solutions are going. I would really appreciate when we talk maybe in a year for an update to see where these different projects with customers are going.

First of all, thank you for your time. And thanks for sharing these insights and I would give the last word to you.

Sebastian

Thanks Madeleine for inviting us here. It was a nice opportunity and I think it’s a great podcast series in any ways. So it’s a fantastic platform to share and also get feedback out of the community. And of course we’d like to see what we both here, Marc and I, SULZER and Innomotics are driving forward to see mature. And see that grow to something bigger of course, because that’s why we’re here for and that’s why we’re in for the game.

Marc

Thanks a lot also from my side and just let us know when you would like to learn more and see you next time. Thanks a lot.

Thank you for the last statement. Thanks that you were part of the podcast and have a great week. Thank you so much and see you. Bye bye.