A Digital Twin for Intelligent Building Technology

Smart buildings have complex building technology that must be monitored and controlled. A digital twin is suitable for this purpose, which in the case of e-magic TwinWorX® even includes a 3D visualization of the entire building. e-Magic Inc. specializes in providing expertise and software for the development and integration of large-scale industrial IoT and Microsoft Azure Digital Twins solutions. The company’s software is used worldwide for monitoring, visualization, control and optimization of buildings, manufacturing facilities and infrastructures.

The challenge: limiting downtime and failures of building technology

Modern industrial buildings are often smart buildings that are monitored and controlled with special building services systems. They contain a variety of different machines, for example, cooling and ventilation systems, heaters, power distributors, circulating pumps, and more, depending on the use of the buildings. The individual pieces of equipment are typically used intensively, resulting in technical difficulties and unplanned outages that disrupt building operations and lead to increased costs.

An important goal in operating a smart building is to reduce these downtimes. Data is helpful for that. They are partly already generated by the existing systems, partly measured by retrofitted sensors. However, many companies store this data in separate silos, so it cannot be analyzed optimally. Therefore, companies do not gain any insights from the data and cannot make it the basis for decisions or use it to control building technology.

The solution: A digital twin monitors important building parameters and alerts in case of malfunctions

e-magic TwinWorX® is an Azure-based platform for building a digital twin, a virtual representation of objects and processes, for example a building with all the objects in it. The platform integrates telemetry data sent from different sources via the Industrial IoT (Internet of Things) and merges them into a digital twin in real time. It is synchronized with the object at a specified frequency and accuracy. An example: An air conditioning system transmits the refrigerant pressure in bar once per second with one decimal place accuracy.

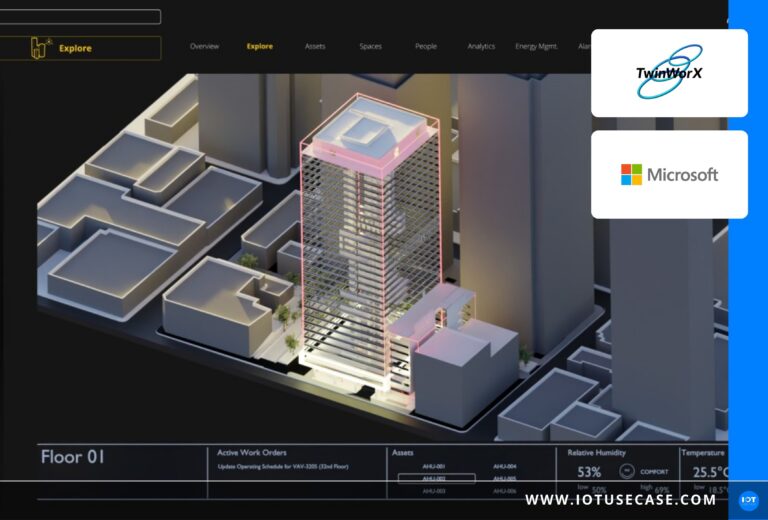

TwinWorX® specializes in building visualization with smart building features. There is a library of numerous standard elements for their representation. In addition, the service supports the import of BIM model data. TwinWorX® Designer uses these different graphic elements to model rooms, objects and people, as well as the properties, capabilities and relationships between them. It then visualizes the solution as an interactive 3D model.

A note: The Digital Twin Definition Language (DTDL) can be used to build the digital twin. It is a description language developed by Microsoft that allows developers to render digital images of physical environments.

The finished digital twin enables processes within the building to be tracked in real time. The software allows defining alarm messages. It automatically sends these alarms to specialist personnel when certain thresholds are exceeded, for example by mail or as a direct message to a smartphone. The continuous acquisition of measurement data enables predictive maintenance.

In addition, the digital twin also supports further analyses, such as scenarios and simulation. This allows technical or structural changes to be tested on the digital twin first. It reacts to these changes in the same way as the real building, so that technicians or architects can optimize any modifications in advance.

The result: The digital twin reduces costs

Digital twins of buildings are efficient tools to improve energy utilization through data analysis. They significantly reduce operating costs. Another important aspect is the reduction of downtime of building technology.

With predictive maintenance, companies can identify potential issues early and fix them in time so they don’t lead to costly downtime. Predictive maintenance also reduces maintenance costs by having technicians come by for maintenance only when it is actually necessary.

Click here to find the app in the Microsoft Azure Marketplace: TwinWorX® – Centralized Monitoring and Control of Facilities