Many companies struggle to implement IoT projects because physically connecting industrial assets to the cloud remains complex and time-consuming, and the prospect of scaling is lacking. CloudRail, in partnership with Microsoft Azure, introduces a way to make IoT implementation fast, reliable and growth-oriented.

The challenge: Connecting different sensors individually to the cloud costs time and money

Today, the connection of industrial machines and devices is often not scalable. Especially older machines and the multitude of different protocols per machine make IIoT projects complex and costly. The heterogeneity of the plant landscape – the mix of brownfield and greenfield – and the associated individual standards and protocols for each machine call for uniform and simple solutions for connectivity. Self-implemented, “tinkered” solutions are usually not scalable and also represent a high risk in terms of IT security. End-to-end solutions, where data is used in a closed application, are often incompatible with overarching platforms such as Microsoft Azure.

The solution: A box, a module and the Internet - that's all it takes

Industrial sensors with analog signals with 4-20mA or IO-Link can be connected to the cloud without prior knowledge. A simple example shows how it works. A temperature, vibration and distance sensor are to be connected to the Microsoft Azure Cloud. The CloudRail.Box is connected to the IO-Link module via Ethernet and simultaneously to the Internet via network cable. The preconfigured interfaces allow easy access to Microsoft Azure. The CloudRail.DMC, a device management service, automatically detects the connected IO-Link module and the wired sensors. These industrial sensors from different manufacturers can now be connected to Microsoft Azure IoT Hub or IoT Central within seconds. Here, the sensor data is automatically normalized so that the data points arrive in the cloud service in human-readable format. For example, the vibration sensor displays acceleration in mm/s^2 and temperature in degrees Celsius. Connecting thousands of sensors is thus faster, easier and can be carried out as a standardized process.

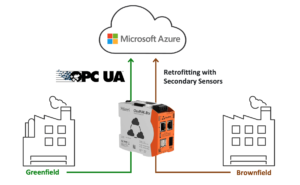

CloudRail thus captures all data from the store floor (OT) and makes it ready for use by the IIoT application (IT). The CloudRail.Box acts as an edge gateway between the store floor and the cloud and is part of the CloudRail Solution. Industry standards of data exchange such as OPC-UA are used to connect modern devices (greenfield), while old machines are retrofitted with secondary sensors in a retrofit approach (brownfield). The CloudRail.Box represents a central point of administration. IoT Plug and Play also enables solution developers to integrate IoT devices into their solutions without manual configuration.

- Plug&Play device provisioning

- Smart Data Normalization

- Edge Computing

- Regular feature and security updates

The result: Time savings in connection and fast ROI

By quickly connecting machines, companies can start with a few use cases, perform ROI considerations, and then scale them into holistic IoT ecosystems.

The CloudRail Device Management Cloud, a cloud-based device management solution, is a central component here. It enables enterprise customers to roll out and manage thousands of globally distributed edge devices – without on-site IT staff at the machines. The devices are installed by maintenance teams and production engineers and then configured remotely via the CloudRail solution. Long-term device management with updates and security patches is also handled by CloudRail’s central device management. Combined with automatic data normalization and device provisioning, the database uses more than 12,000 sensor definitions to reduce the setup time for connecting a machine to the cloud from weeks to just hours.

Initial findings from the PoC (proof of concept) with Azure IoT Central can also be used to validate hypotheses, which in turn can be used to build entire IIoT roadmaps or initiate process optimizations.

Because the scalable solution integrates seamlessly with Microsoft Azure IoT Services into a data lake (big data store of raw data), it counteracts data silo issues, heterogeneous data storage in enterprises. The data is also available to other Microsoft services – a rollout of a complete IIoT ecosystem on Microsoft Azure.

CloudRail, in conjunction with Microsoft Azure’s offering, delivers lower device onboarding hurdles, predictable management costs, and fast results. The solution is ideal for large-scale IIoT projects that need to meet functionality, scalability and IT security requirements from the first pilot.