About Daubert Chemical

Daubert Chemical was founded in 1935 with companies in the steel industry as its first major customers. In 1940, the company changed its name from Nox-Rust Chemical Company to Daubert Chemical and during World War II, began producing corrosion preventive products for the US Navy. Today, Daubert Chemical has become a world leader in corrosion prevention, adhesives, sound dampening, and specialty coatings. Their down-to-earth “can do” approach to solving issues is the reason the company has become a preferred choice by engineers in the transportation, automotive, steel, and general manufacturing industries. Daubert Chemical continues its commitment to understanding customer needs to deliver innovative solutions for greater market success.

Project Summary

Daubert Chemical wanted better insight and visibility into its operations to improve operational efficiency but also wanted to reduce periods of downtime through better alarm management capabilities. The company also realized that data collection would be highly beneficial and understood that to achieve these goals, it needed to upgrade its processes with automation software. The company opted to start small to test out such a system and chose to first work with system integrator Sulzer Consulting at the beginning of the project. It was Sulzer Consulting that introduced Daubert to ICONICS. Later, Daubert worked with system integrators RSI and then ECS LLC. Sulzer Consulting is located in Sussex, Wisconsin and its mission is to provide customers with reliable, high-quality technology, tools, and training. A Gold Certified member of the ICONICS System Integrator Program, RSI is a small and growing business in Cody, Wyoming that provides cost-effective high-quality automation solutions to customers in a variety of areas. Lastly, Daubert also utilized ECS LLC (Madison, Wisconsin) for independent consulting work with ICONICS.

ICONICS Products Deployed

Realized Real-Time Benefits

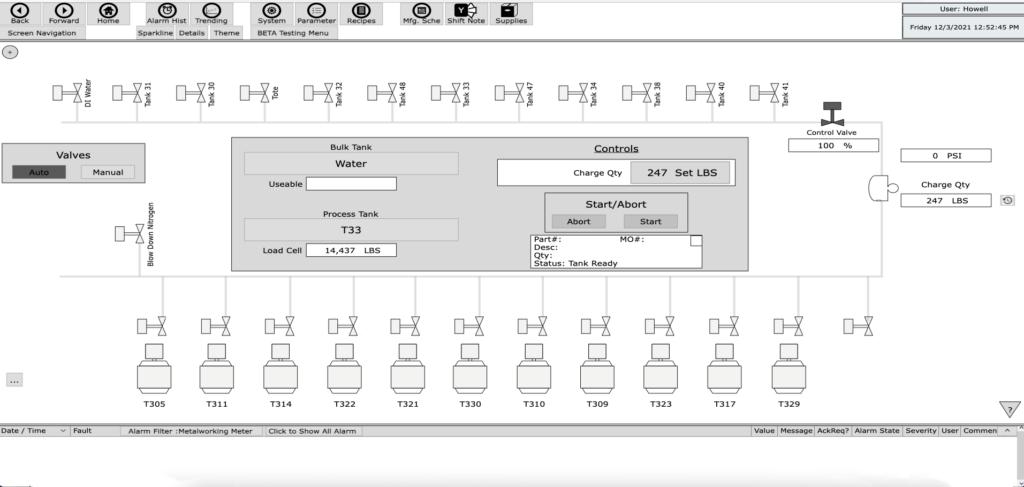

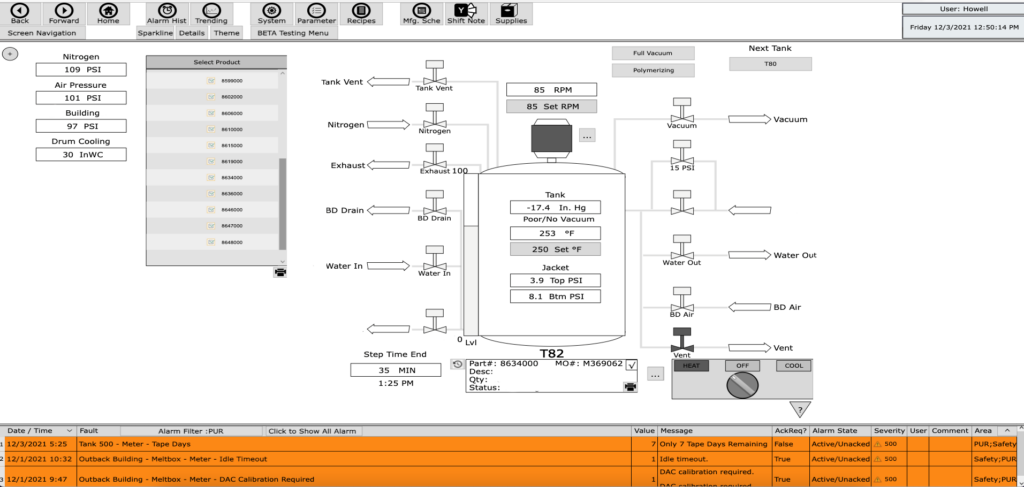

Daubert Chemical has realized real-time benefits with the ICONICS platform. For example, GENESIS64 provides alarming capability, data collection, and process visibility. Additionally, GraphWorX and WebHMI allow the company to deliver HMI to any computer within the organization: in offices, on the plant floor, wherever personnel are within the facility. The software also provides useful technological support since the company has limited IT personnel with their main responsibilities of managing its network servers and hardware. As ICONICS is also an extremely scalable platform, every new piece of equipment Daubert acquires can be easily and efficiently integrated into the system allowing for immediate communication of information across assets.

As a result, Daubert can monitor and control its processes far better. Due to the vastly improved operational awareness that ICONICS software provides, the company has reduced the number of process incidents and problems resulting in improved and consistent quality assurance. Moreover, when there are problems, the company can quickly look at the available data to see what happened to then take corrective measures. In fact, unsolved problems have been reduced by 75%. In addition, the alarming capability has been extremely advantageous, allowing Daubert to take action to prevent problems; and in some cases serious problems, and empowers its personnel to implement preventive measures for future problems. Lastly, Daubert Chemical has realized increased operational efficiency and work collaboration and has improved the overall quality of its products.

Conclusion

Daubert Chemical’s use of the ICONICS Suite has been a journey, one that started off simply with a specific need for alarm capability and data collection, and slowly grew over time, step by step, to a key business platform of a company-wide SCADA system. Daubert Chemical has had an excellent experience with ICONICS as a positive business model that is affordable, modular, and scalable, with an emphasis on the ability to start small with pilot projects and then scale from there. From the beginning, the company slowly started learning about the individual ICONICS modules to understand where these best fit into their operations. The company has increased both its tag counts and HMI licenses several times over, starting with 75 tags in 2009 and growing to 5000 tags with GENESIS64 and Hyper Historian to date. Currently, Daubert has one server and 44 WebHMI client licenses and with knowledge of the available ICONICS products, will continue to analyze where these applications can be used throughout their manufacturing operations. The company is also planning to install a new cloud ERP system. With a long-standing and strong partnership with Microsoft and its products, ICONICS’ cloud-ready platform can assist with this system upgrade. Daubert Chemical is ever-evolving in its digital journey and with each technological expansion and improvement, envisions using more ICONICS products.

ICONICS business model and software tools have allowed us to improve quality and efficiency on an ongoing basis. They are a key contributor to our continuing manufacturing improvements and success.

Doug Howell

Director – Polyurethanes

Daubert Chemical Company

Text taken over from the original – ICONICS