Every production needs a suitable home. This home must be maintained and serviced for the company to operate profitably under its roof in the long run. In building technology, there is often a lot of potential for digital solutions that simplify processes, contribute to energy efficiency and thus save time and money. But it doesn’t have to be a new building: With KIS.ME, RAFI offers various solutions for retrofitting building technology.

The challenge: Identifying problems in the building before they affect production

The condition and maintenance of a company building are, in most cases, the responsibility of an individual or department that is minimally or not at all involved in the digitalization of the company. However, building technology greatly benefits from digital solutions. The aim is to simplify processes and, at the same time, to identify starting points for improvements, for example, how often a particular event actually occurs and what factors play a role. How often a condensate water collection container is full and needs to be emptied, for example, directly depends on weather conditions, specifically the humidity in the air. A building operator must also have precise knowledge of all consumption data in order to be able to derive possible improvement measures or necessary changes. Even if certain media such as compressed air are only to be available during ongoing production for cost reasons, the startup and shutdown must be carried out somehow. Manual inspections, i.e. tours of the building, are not only time-consuming, but the results also need to be documented in a way that they can be further processed elsewhere. In addition, just as in production itself, the various plants in a building supply system vary in age and are therefore very differently suited for digital queries. Some systems shut down in the event of a malfunction – which is usually good at first to avoid major problems. However, this standstill must also be noticed by the right people, ideally not just on the next routine inspection run, but immediately, or even better, the plant sends data that can be used to identify a problem in advance.

The solution: Uncomplicated digital representation of states, even for older machines and plants

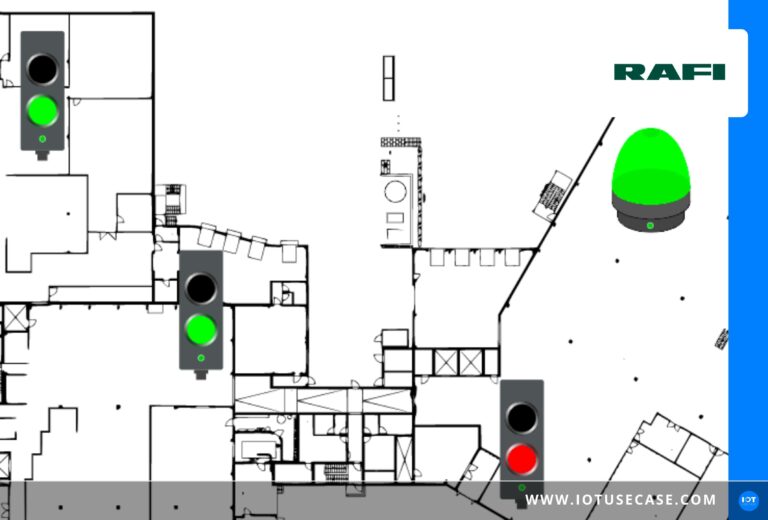

With KIS.ME, RAFI has developed a platform to optimize and digitalize manual processes that still predominate in many areas of numerous companies. RAFI has been a specialist for electromechanical products for more than 125 years and provides the necessary hardware components for the successful digital retrofit of building technology. Human-machine interfaces have always been the focus here. KIS.ME combines a cloud-based platform for management and various devices for signals. This can be a signal lamp, an IO box or an individually configurable pushbutton. All devices have digital inputs and outputs through which they are connected to the machines and the sensors. Data is transmitted exclusively via WLAN, so no additional disruptive cabling is required. All data management, analysis and visualization on a dashboard is performed on the platform, HIS.Manager. There, the responsible persons determine which signal should trigger which action in each case. This can be an automatic e-mail to certain people, for example when a level sensor indicates that a container needs to be emptied or when a system reports that a limit value has been exceeded. With the KIS.ME devices, it is possible to connect even older plants to the digital information processing of the IoT, making the entire technology more transparent and ultimately more efficient.

The result: Processes are optimized, improvement potentials are identified

Digital solutions such as KIS.ME can save money immediately by reducing the need for manual processes, whether for inspection or for switching equipment on or off. Be it through sensor signals transmitted via WLAN and displayed on a dashboard at a location of choice, or through the control of valves in the case of demand-based compressed air supply.

But the retrofit of building technology holds much more potential. The detailed data on plant conditions and consumption open up starting points for improvements; a digital twin and digital building plans reflect the current situation at all times, and remote access from mobile devices facilitates maintenance. The cloud is available to any number of users in the company, and the administrator assigns the various access authorizations. As a result, other departments up to management level can easily access the building data, configure the dashboard individually and integrate the information into planning processes.