Monitoring machine data centrally across multiple sites requires connecting machines to the IIoT. If data processing and alarming are to be added, it becomes more complex. In such cases, preconfigured solutions relieve the burden on the user’s resources.

The challenge: Avoiding production downtime by evaluating pneumatic wear data

SMC Deutschland GmbHis a manufacturer, partner and solution provider for pneumatic and electric automation technology. One of their customers is an automotive supplier that uses SMC drives to press in plastic lids in a specific manufacturing step. This is done by means of a pneumatic pusher, which must apply a certain force at a specified position. This ensures that the lid is cleanly engaged.

In order to achieve consistently high component quality, this press-in pressure is to be permanently monitored centrally. However, the automotive supplier’s production is spread across many locations worldwide. The data should be protected absolutely securely from external access and SMC wanted a solution that could be implemented very easily and without additional internal resources.

The solution: From event-driven to predictive maintenance through IoT

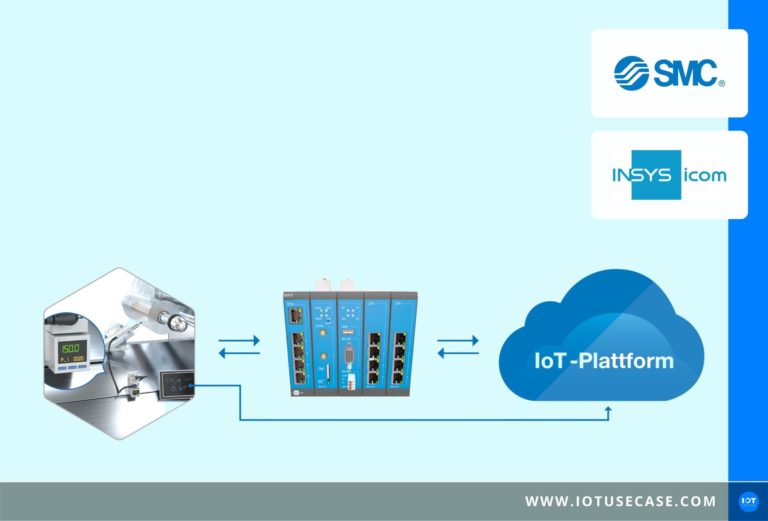

This solution was implemented by INSYS icom, a premium manufacturer for routers and gateways made in Germany, which offers complete solutions for IIoT projects – data communication with security solution as a total service.

In this use case, an MRX 3 series router was installed, right on the machine next to the controller. The machine controller sends the data to the router, which forwards them to the control center, where they are stored and further used for analysis purposes. Transfer to pre-integrated cloud systems or generically via MQTT is also possible. Compared to a simple gateway solution, the router has the advantage that data transfer can take place in a highly secure manner via VPN: IT security at KRITIS level. The basic variants DSL, LTE and LAN can be supplemented as required with additional plug-in cards (MRcards) – also with customer-specific MRcards. Two digital inputs are already included in all variants. The icom Data Suite on Linux extends the functionality and turns the router into a protocol converter and data logger – without requiring any programming knowledge on the part of the user. These applications are configured rather than programmed, which saves resources. The integrated data logger quickly and easily provides data for verification, failure analysis and reports. It captures data, records it and sends it as a CSV file. The values can then be evaluated using a standard program such as Excel.

With the routers, SMC can not only read out the machine data, but also process it. This allows SCADA, MES or multi-clouds to be connected, threshold values to be monitored and alarms to be triggered as soon as the threshold values are exceeded or undershot. Thanks to a Linux container environment on the routers, the routers can also be equipped with additional functions and their own applications – completely isolated from the router firmware.