The home appliance manufacturer Tefal has upgraded its site with energy and wastewater management. They use the GENESIS64 platform from ICONICS and its solutions for monitoring wastewater production. This enables the company to reduce its energy costs and monitor the environmental impact of the wastewater system.

The challenge: Energy management in production and monitoring the wastewater system

Groupe SEB (Société d’Emboutissage de Bourgogne) is a French consortium that manufactures small home appliances and cookware. One of the company’s best-known brands is Tefal SAS, which operates a production facility in Rumilly (France). The site employs around 1,850 people on an area of 160,000 square meters. Tefal manufactures around 44 million products there every year. The energy costs for production amount to eight million euros, with half of it for electricity and gas. At the same time, fresh water is required for production, which necessitates the operation of its own wastewater system. It consists of a wastewater treatment plant, eight discharge points and seven valve chambers for valves and pumps.

In its environmental strategy, Groupe SEB has committed itself to combating climate change and implementing innovative solutions. For this reason, the company management has decided on two measures:

- An energy efficiency project to reduce production-related energy costs

- A monitoring solution for the wastewater network that enables a quick responses to faults.

Tefal chose the global company ICONICS as its service provider for both projects. The company, which is part of the Mitsubishi Electric Group, specializes in automation solutions and offers these as a Microsoft Gold Partner in the Azure Store, among other things.

The solution: The GENESIS64 platform can network any system for intelligent monitoring

The core of the solution is the GENESIS64 platform from ICONICS. The suite connects the production level with the IT level and is known for its simple and intuitive operation. It enables companies to transfer machine and process data in real time to a web-enabled visualization dashboard. For this purpose, it is connected to systems such as BMS (Building Management Systems), SCADA (Supervisory Control and Data Acquisition), ERP (Enterprise Resource Planning) and other control systems. It supports all common industry protocols such as OPC UA, MQTT, Modbus and others.

Energy management with Energy AnalytiX

To reduce energy consumption and the associated costs, Tefal uses the energy management solution from ICONICS. In addition to the GENESIS64 HMI/SCADA Suite, this solution also includes the Energy AnalytiX software as well as visualization and reporting modules. The system enables precise monitoring and analysis of energy consumption in real time, allowing Tefal to identify consumption patterns and control all systems efficiently.

Energy management with the ICONICS software enables real-time visualization of energy consumption data so that consumption trends can be responded to immediately. Energy AnalytiX offers consumption calculations and analyses, a data historian for recording data histories and convenient visualization tools. The software is intuitive to configure, customize and operate.

Wastewater management with monitoring

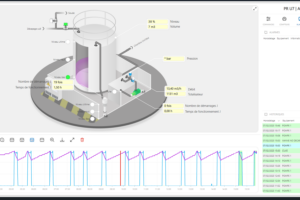

For the wastewater management, Tefal first had to revise the wastewater system and, among other things, technically upgrade the eight discharge points. The system integrator Calasys then implemented a solution based on the GENESIS64 platform from ICONICS. It is used to automate and optimize the wastewater network. The intuitive operation enables information to be called up quickly.

Tefal can now monitor important key figures such as operating times and quantities and control them accordingly. In this way, the company also achieves improved energy efficiency in the operation of the wastewater system. The new software solution also supports alarm responses and the quick resolution of technical problems. This enables the company to react quickly and avoid the risks of pollution for the river and the surrounding ecosystem.

The result: Monitoring energy consumption and wastewater condition

With the new energy management solution, Tefal is able to automatically record energy consumption in production by appliance, area and location. Furthermore, the company can calculate costs such as energy per unit more accurately and capture production efficiency more precisely.

In wastewater treatment, the operations team uses the dashboards to monitor key performance indicators. This includes the number of actuator starts, operating time, and wastewater quantities. In this way, the team can ensure that the wastewater system functions properly and does not cause any environmental damage.